Unlock the Power of Parker VFDs: Discover Their Game-Changing Features for Industrial Success!

Variable Frequency Drives (VFDs) are essential components in the modern industrial landscape, acting as the backbone of motor control systems. These devices allow for precise regulation of motor speed and torque, ensuring that machinery operates efficiently and effectively. Among the various VFDs available in the market, Parker VFDs have emerged as a trusted solution for industries seeking to enhance their operational capabilities. With a focus on innovation and performance, Parker VFDs embody the latest advancements in technology, making them a compelling choice for a wide range of applications. In this article, we will dive deeper into what Parker VFDs are, explore their remarkable features, and discuss their significance in industrial applications.

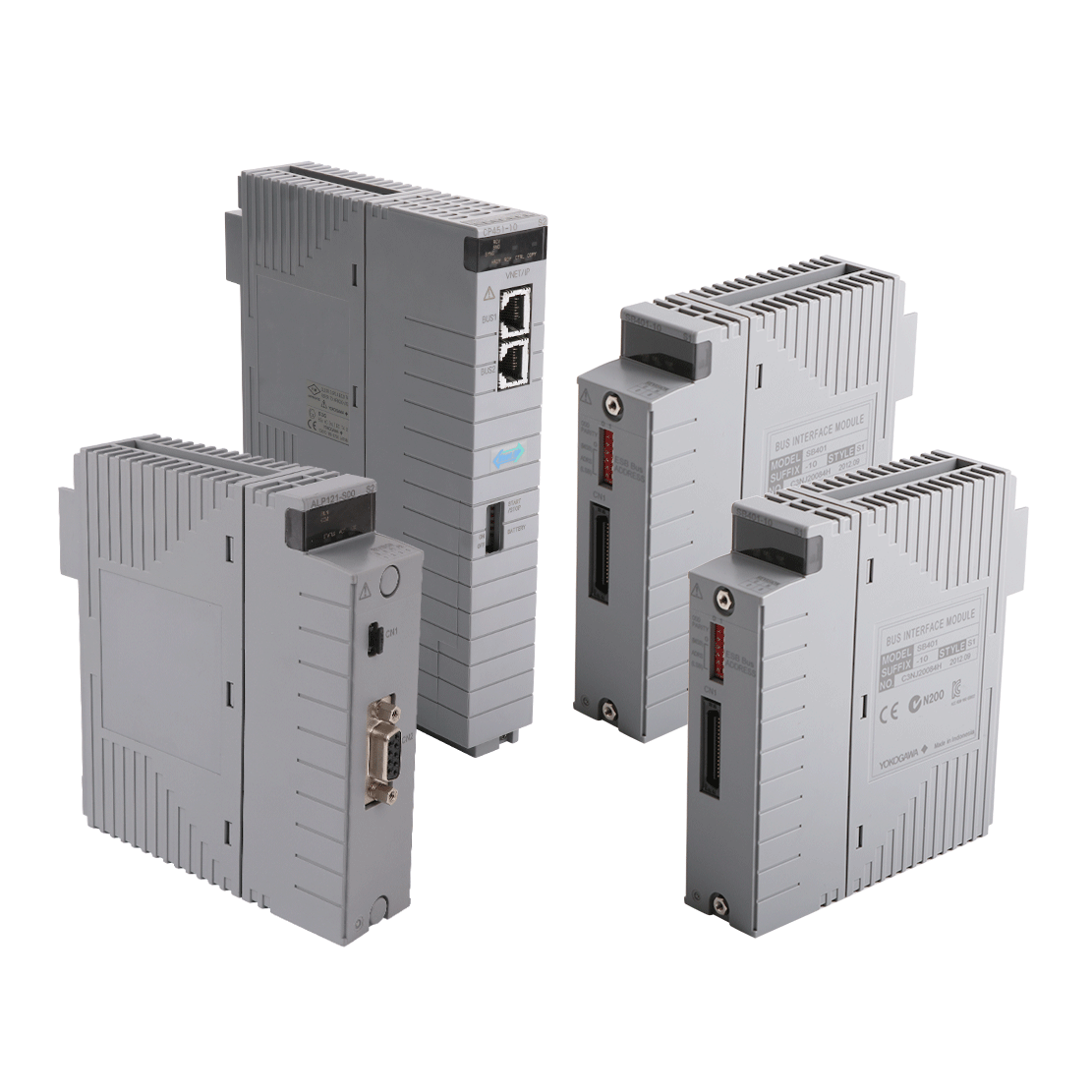

Understanding Parker VFDs

Parker VFDs are specialized devices designed to control the speed and torque of electric motors through variable frequency and voltage adjustments. They function by converting the fixed frequency of the power supply into a variable frequency output, allowing for fine-tuned motor control. This capability is crucial in various industrial settings where precise speed adjustments can lead to improved productivity and reduced energy consumption. The significance of Parker VFDs lies in their ability to seamlessly integrate with existing systems, providing reliable performance and flexibility in motor operations. By enhancing the efficiency of motor-driven systems, Parker VFDs not only optimize performance but also contribute to the sustainability goals of industries by lowering energy usage.

Key Features of Parker VFDs

Parker VFDs boast a range of features that set them apart from conventional drives. One of their standout characteristics is energy efficiency; these drives are engineered to minimize energy losses, thereby reducing operational costs. Advanced control algorithms allow for precise motor control, enabling smoother operations and minimizing vibrations, which can lead to wear and tear on machinery. Additionally, Parker VFDs come equipped with user-friendly interfaces that facilitate easy programming and monitoring. This accessibility allows operators to quickly adapt settings to meet fluctuating operational demands. The incorporation of built-in diagnostics further enhances their value, providing real-time feedback and alerts that help prevent potential failures before they occur. Overall, these features collectively contribute to operational efficiency and significant cost savings for industries.

Applications of Parker VFDs in Industries

Parker VFDs find application in a multitude of industries, each benefiting from their superior control capabilities. In manufacturing, for instance, they are used in conveyor systems, pumps, and fans, allowing for precise speed control that enhances production rates and product quality. HVAC systems leverage Parker VFDs to regulate airflow and temperature, improving energy efficiency while maintaining comfort levels in large buildings. Renewable energy applications, such as wind turbines and solar systems, also utilize these drives to optimize energy conversion and distribution. A friend of mine who works in a manufacturing plant shared how implementing Parker VFDs allowed their team to reduce energy consumption by over 30%, showcasing the tangible benefits these drives can deliver. Such diverse applications highlight the versatility of Parker VFDs and their role in enhancing performance and reliability across various sectors.

Benefits of Using Parker VFDs

The benefits of integrating Parker VFDs into industrial applications are manifold. One of the most significant advantages is improved energy savings; by adjusting motor speed to match load requirements, these drives can dramatically lower energy consumption. This not only translates into cost savings but also aligns with environmental sustainability goals. Additionally, Parker VFDs reduce wear and tear on equipment, leading to longer lifespans for motors and associated machinery. This reduction in maintenance needs can further enhance productivity, as less downtime is required for repairs. Enhanced process control is another key benefit, allowing industries to achieve consistent quality in their outputs. Collectively, these advantages contribute to greater overall productivity, making Parker VFDs an invaluable asset in any industrial setting.

Key Takeaways on Parker VFDs

In summary, Parker VFDs are a powerful solution for industries seeking to optimize motor control and enhance operational efficiency. Their advanced features, coupled with a wide range of applications, make them a crucial component in modern industrial systems. The benefits they offer—ranging from energy savings to improved process control—underscore their importance in achieving industrial success. As industries continue to prioritize efficiency and sustainability, considering the implementation of Parker VFDs could be a game-changing decision that propels operations to new heights.