In modern manufacturing and construction, precision is no longer a luxury—it is an operational necessity. As industries demand higher cutting accuracy, longer tool life, and better finish quality, Fangda introduces a solution that embodies all these qualities: the TCT Circular Saw Blade. Built with advanced material engineering and application-driven design, this product represents a core cutting technology for professional users.

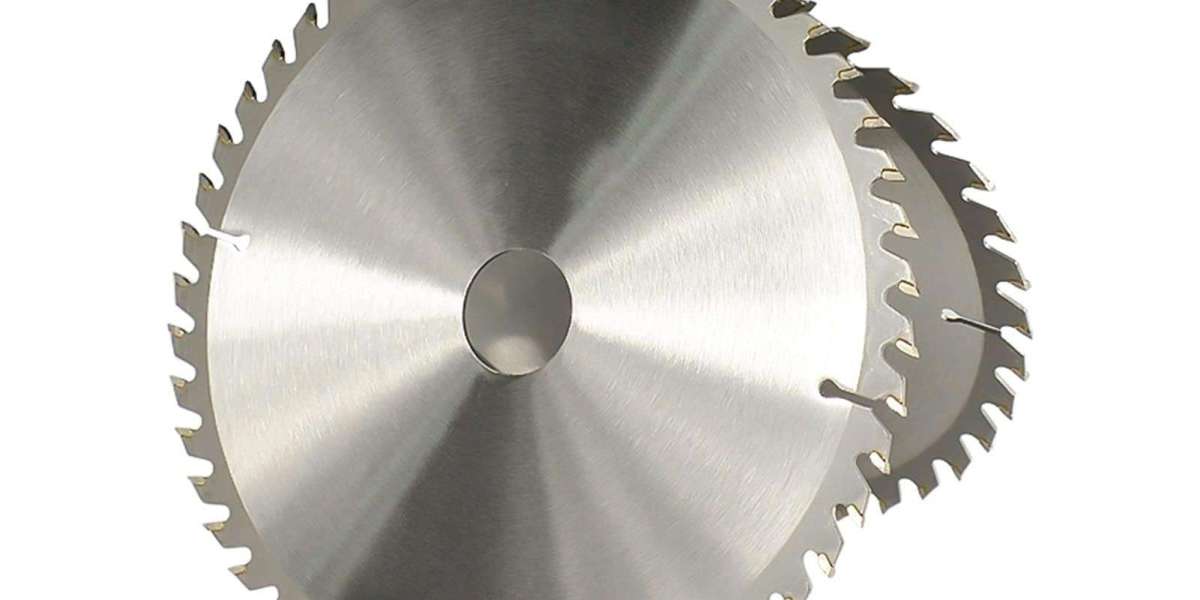

The acronym TCT stands for Tungsten Carbide Tipped, which refers to the integration of ultra-hard carbide inserts at the cutting edge of each tooth. Compared to standard steel blades, TCT blades exhibit much greater hardness, heat resistance, and wear durability. Circular Saw Blade features a precision-ground tooth profile optimized for cutting both hardwood and non-ferrous metals like aluminum and copper. This versatility makes it ideal for use in cabinetmaking, framing, window fabrication, and light metal work.

What sets it apart is its commitment to blade geometry. Each tooth is spaced at carefully calculated intervals to reduce vibration and ensure a smoother feed rate. The result is not only a cleaner cut but also reduced operator fatigue and lower energy consumption over extended use. The combination of alternate top bevel (ATB) or triple chip grind (TCG) tooth configurations further enhances performance across specific materials.

Beyond the edge, the core design of Saw Blade plays a significant role in operational stability. Laser-cut expansion slots and heat-resistant steel cores are used to prevent warping and maintain structural integrity even under high-speed, high-load applications. This feature is especially important for CNC cutting centers or automated saw systems that demand consistency over hundreds of cuts.

To maintain it's high quality standards, every blade undergoes strict inspections—including flatness testing, tensioning, and edge uniformity. These quality control steps ensure that the final product not only meets but often exceeds expectations for performance under industrial workloads.

Compatibility is another strength. It's blades are engineered to fit most commercial machines, from table saws and miter saws to beam saws and crosscut units. This universal fit allows businesses to adopt the blade without needing specialized adapters or machinery modifications.

Finally, Saw Blade offers a practical edge: reduced tool change intervals and minimized downtime. By maintaining sharper edges longer, it reduces material waste, improves cutting finish, and supports higher throughput in production lines.

For professionals in woodworking, construction, furniture making, and light metal fabrication, Fangda's blade offers a dependable and efficient solution. It is a tool designed not just to cut—but to cut smart, cut clean, and cut consistently.To explore full product details, visit: https://www.fangda-tools.com/product/hole-saws/