"Future of Executive Summary Cement Kiln Co-Processing Fuels Market: Size and Share Dynamics

CAGR Value

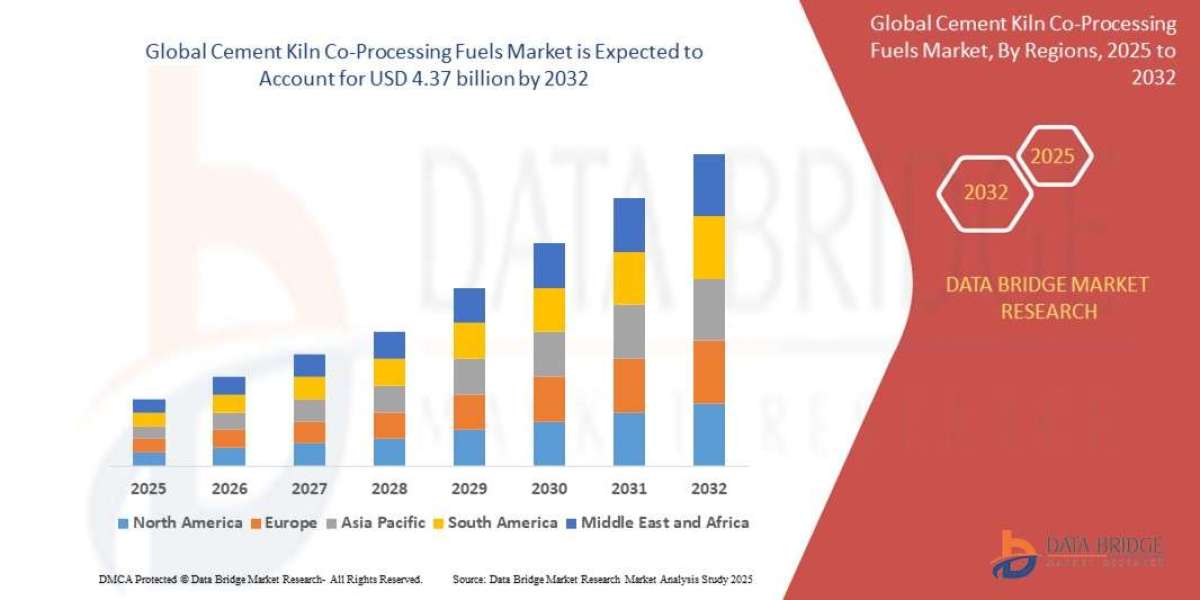

During the forecast period of 2025 to 2032 the market is likely to grow at a CAGR of 4.80%, primarily driven by growing need for sustainable and cost-effective waste management solutions

Cement Kiln Co-Processing Fuels Market research report is a sure solution to get market insights with which business can visualize market place clearly and thereby take important decisions for growth of the business. By getting an inspiration from the marketing strategies of rivals, businesses can set up inventive ideas and striking sales targets which in turn make them achieve competitive advantage over its competitors. Cement Kiln Co-Processing Fuels Market report inspects the market with respect to general market conditions, market improvement, market scenarios, development, cost and profit of the specified market regions, position and comparative pricing between major players.

An influential Cement Kiln Co-Processing Fuels Market report conducts study of market drivers, market restraints, opportunities and challenges underneath market overview which provides valuable insights to businesses for taking right moves. This market report is a source of information about Cement Kiln Co-Processing Fuels Market industry which puts forth current and upcoming technical and financial details of the industry to 2029. The report is a window to the Cement Kiln Co-Processing Fuels Market industry which defines properly what market definition, classifications, applications, engagements and market trends are. Moreover, market restraints, brand positioning, and customer behavior, is also studied with which achieving a success in the competitive marketplace is simplified.

Tap into future trends and opportunities shaping the Cement Kiln Co-Processing Fuels Market. Download the complete report:

https://www.databridgemarketresearch.com/reports/global-cement-kiln-co-processing-fuels-market

Cement Kiln Co-Processing Fuels Market Environment

**Segments**

- **Type**: The global cement kiln co-processing fuels market can be segmented based on type into solid, liquid, and gaseous fuels. Solid fuels, such as coal, petcoke, and biomass, are commonly used in cement kilns for their energy content and ease of handling. Liquid fuels, like waste oils and solvents, are also utilized as alternative fuels in cement kilns. Gaseous fuels, including natural gas and biogas, offer clean combustion and are considered environmentally friendly options for cement production.

- **End-User Industry**: Cement kiln co-processing fuels find applications across various end-user industries such as cement manufacturing, waste management, and energy production. Cement manufacturing is the primary sector driving the demand for these fuels, as they help in reducing carbon emissions and improving energy efficiency in the production process. Waste management companies utilize co-processing fuels as a sustainable solution for managing and disposing of waste materials while generating energy.

- **Geography**: Geographically, the market for cement kiln co-processing fuels can be segmented into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Each region has its unique market dynamics and regulations regarding the use of alternative fuels in cement production. With increasing focus on sustainable practices and stringent environmental norms, the demand for co-processing fuels is expected to rise significantly across all regions.

**Market Players**

- **Holcim Ltd.**: A global leader in building materials and solutions, Holcim Ltd. has been actively involved in promoting the use of alternative fuels in cement production. The company's innovative approaches to co-processing fuels have set industry benchmarks for sustainability and efficiency.

- **HeidelbergCement AG**: Known for its commitment to sustainability and environmental stewardship, HeidelbergCement AG has implemented co-processing fuel strategies across its global operations. The company's focus on circular economy principles has helped in reducing its carbon footprint and achieving sustainable growth.

- **Cemex S.A.B. de C.V.**: With a strong presence in the cement industry, Cemex S.A.B. de C.V. has adopted co-processing fuels as part of its sustainability initiatives. By utilizing alternative fuels in cement kilns, the company has been able to lower its greenhouse gas emissions and contribute to a greener future.

- **LafargeHolcim**: LafargeHolcim is a key player in the cement kiln co-processing fuels market, leveraging its expertise in alternative fuel technologies to drive innovation and environmental performance. The company's strategic partnerships and investments in cleaner energy sources position it as a frontrunner in sustainable cement production.

In conclusion, the global cement kiln co-processing fuels market is witnessing significant growth driven by increasing environmental concerns, regulatory support for alternative fuel usage, and the adoption of sustainable practices by key industry players. The market is characterized by a diverse range of fuel types, end-user applications, and geographic regions, offering ample opportunities for market expansion and technological advancements.

The global cement kiln co-processing fuels market is poised for continued growth and evolution, driven by several key factors shaping the industry landscape. One emerging trend in the market is the increasing focus on circular economy principles, where the emphasis is placed on resource efficiency, waste reduction, and sustainable production practices. Market players are increasingly adopting co-processing fuels as a means to not only reduce carbon emissions but also to contribute towards a more circular and sustainable economy. This shift towards circular economy models is expected to drive innovation and collaboration within the industry, leading to the development of more advanced and efficient fuel processing technologies.

Another significant trend in the market is the rising demand for bio-based fuels as a more environmentally friendly alternative to traditional fossil fuels. Biomass-derived fuels, such as agricultural residues, wood chips, and other organic materials, are gaining traction in the cement industry due to their renewable nature and lower carbon footprint. Market players are investing in research and development to optimize the use of bio-based fuels in cement kilns, exploring new feedstock sources and refining production processes to enhance efficiency and reduce overall environmental impact.

Moreover, the market is witnessing increased regulatory support and incentives for the use of alternative fuels in cement production. Governments and regulatory bodies across various regions are introducing policies and measures to encourage the adoption of sustainable fuel sources and reduce reliance on fossil fuels. This regulatory backing is creating a favorable environment for market growth, as cement manufacturers are incentivized to invest in co-processing technologies and embrace more environmentally friendly practices.

Furthermore, the market is witnessing a surge in strategic collaborations and partnerships among industry players to drive innovation and technological advancements in fuel processing. Companies are joining forces to share expertise, resources, and best practices in sustainable fuel utilization, leading to the development of more efficient and cost-effective solutions. These collaborative efforts are expected to propel the market forward, fueling the adoption of co-processing fuels and accelerating the transition towards greener cement production practices.

Overall, the global cement kiln co-processing fuels market is experiencing a period of transformation characterized by sustainability, innovation, and collaboration. As market players continue to prioritize environmental responsibility and operational efficiency, the adoption of alternative fuels is expected to become more widespread, driving further growth and advancements in the industry. The future of the market lies in continuous innovation, regulatory compliance, and strategic partnerships, setting the stage for a more sustainable and resilient cement manufacturing sector.The global cement kiln co-processing fuels market is undergoing a significant transformation driven by various factors that are reshaping the industry landscape. One key trend shaping the market is the increasing shift towards circular economy principles, emphasizing resource efficiency, waste reduction, and sustainable production practices. Market players are progressively adopting co-processing fuels not only to reduce carbon emissions but also to contribute to a more circular and sustainable economy. This transition towards circular economy models is expected to foster innovation and collaboration within the industry, leading to the development of more advanced and efficient fuel processing technologies.

Another noteworthy trend in the market is the escalating demand for bio-based fuels as a more environmentally friendly alternative to traditional fossil fuels. Biomass-derived fuels, such as agricultural residues and wood chips, are gaining popularity in the cement industry due to their renewable nature and lower carbon footprint. Companies are investing in research and development to optimize the use of bio-based fuels in cement kilns, exploring new feedstock sources and refining production processes to enhance efficiency and reduce environmental impact.

Moreover, regulatory support and incentives for the use of alternative fuels in cement production are on the rise across various regions. Governments and regulatory bodies are introducing policies to encourage the adoption of sustainable fuel sources and reduce reliance on fossil fuels. This regulatory backing is fostering a favorable environment for market growth, as cement manufacturers are incentivized to invest in co-processing technologies and embrace more environmentally friendly practices.

Additionally, the market is witnessing a surge in strategic collaborations and partnerships among industry players to drive innovation and technological advancements in fuel processing. Companies are pooling resources and expertise to develop more efficient and cost-effective solutions for sustainable fuel utilization. These collaborative efforts are expected to propel the market forward, accelerating the adoption of co-processing fuels and facilitating the transition towards greener cement production practices.

In conclusion, the global cement kiln co-processing fuels market is evolving rapidly, characterized by a focus on sustainability, innovation, and collaboration. As the industry continues to prioritize environmental responsibility and operational efficiency, the widespread adoption of alternative fuels is anticipated, leading to further growth and advancements in cement manufacturing. The future of the market hinges on ongoing innovation, regulatory compliance, and strategic partnerships, paving the way for a more sustainable and resilient cement industry.

Evaluate the company’s influence on the market

https://www.databridgemarketresearch.com/reports/global-cement-kiln-co-processing-fuels-market/companies

Forecast, Segmentation & Competitive Analysis Questions for Cement Kiln Co-Processing Fuels Market

- How large is the Cement Kiln Co-Processing Fuels Market currently?

- At what CAGR is the Cement Kiln Co-Processing Fuels Market projected to grow?

- What key segments are analyzed in the Cement Kiln Co-Processing Fuels Market report?

- Who are the top companies operating in the Cement Kiln Co-Processing Fuels Market?

- What notable products have been introduced recently in the Cement Kiln Co-Processing Fuels Market?

- What geographical data is included in the Cement Kiln Co-Processing Fuels Market analysis?

- Which region is experiencing the quickest growth in the Cement Kiln Co-Processing Fuels Market?

- Which country is forecasted to lead the Cement Kiln Co-Processing Fuels Market?

- What region currently holds the biggest share of the Cement Kiln Co-Processing Fuels Market?

- Which country is likely to show the highest growth rate in coming years?

Browse More Reports:

Europe Silicon Anode Material Battery Market

Middle East and Africa Silicon Anode Material Battery Market

North America Silicon Anode Material Battery Market

Europe RF Over Fiber Market

North America RF Over Fiber Market

Asia-Pacific Semiconductor IP Market

Europe Semiconductor IP Market

Middle East and Africa Semiconductor IP Market

North America Semiconductor IP Market

Middle East and Africa Vehicle Motorized Door Market

Asia-Pacific Water Sink Market

Middle East and Africa Water Sink Market

Asia-Pacific Meat Extract Market

Europe Meat Extract Market

Middle East and Africa Meat Extract Market

Global Companion Animal Diagnostic Market

About Data Bridge Market Research:

An absolute way to forecast what the future holds is to comprehend the trend today!

Data Bridge Market Research set forth itself as an unconventional and neoteric market research and consulting firm with an unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process. Data Bridge is an aftermath of sheer wisdom and experience which was formulated and framed in the year 2015 in Pune.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email:- [email protected]

"