Metallurgy for the abyss

Standard 52100 steel would embrittle at −4 °C seafloor temperatures; instead, super-duplex stainless steel (UNS S32760) with 25 % Cr and 3.5 % Mo is used. Charpy values remain above 120 J at −50 °C, ensuring the carriage absorbs 50 kN surge loads without fracture. A 50 µm electroless nickel-tungsten coating adds sacrificial corrosion resistance, validated by 5 000 h salt-fog testing.

Standard 52100 steel would embrittle at −4 °C seafloor temperatures; instead, super-duplex stainless steel (UNS S32760) with 25 % Cr and 3.5 % Mo is used. Charpy values remain above 120 J at −50 °C, ensuring the carriage absorbs 50 kN surge loads without fracture. A 50 µm electroless nickel-tungsten coating adds sacrificial corrosion resistance, validated by 5 000 h salt-fog testing.

Dry lubrication that never dries out

Grease would wash away; therefore WS₂ is sputtered onto raceways at 200 °C, forming a 300 nm crystalline film oriented along the (002) basal plane. Auger spectroscopy shows <5 % wear after 1 million cycles at 10⁻⁷ mbar equivalent pressure. A secondary reservoir of MoS₂ micro-pellets in the cage releases fresh lamellae when shear exceeds 300 MPa, guaranteeing 25-year service life.

Grease would wash away; therefore WS₂ is sputtered onto raceways at 200 °C, forming a 300 nm crystalline film oriented along the (002) basal plane. Auger spectroscopy shows <5 % wear after 1 million cycles at 10⁻⁷ mbar equivalent pressure. A secondary reservoir of MoS₂ micro-pellets in the cage releases fresh lamellae when shear exceeds 300 MPa, guaranteeing 25-year service life.

Multi-barrier sealing

An outer FFKM O-ring rated to 350 bar blocks seawater ingress. Inside sits a 0.3 mm silicone grease layer that doubles as a leak detector: pressure drop triggers an acoustic transponder alerting topside crews within 30 seconds. The seal cartridge is moulded for ROV replacement in 15 minutes, eliminating divers.

An outer FFKM O-ring rated to 350 bar blocks seawater ingress. Inside sits a 0.3 mm silicone grease layer that doubles as a leak detector: pressure drop triggers an acoustic transponder alerting topside crews within 30 seconds. The seal cartridge is moulded for ROV replacement in 15 minutes, eliminating divers.

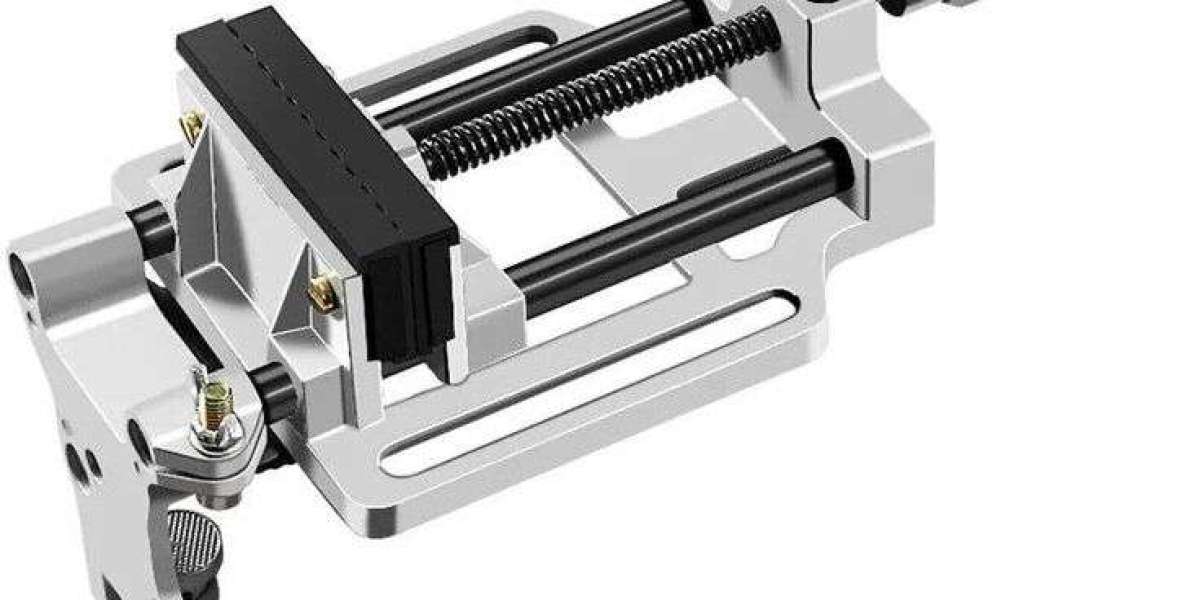

Structural integrity under 400-ton loads

The 600 mm stroke bearing is integrated into a 150 mm × 150 mm titanium box beam with 8 mm wall thickness. Finite-element analysis shows the first Euler buckling mode at 9 800 N—four times the peak operational load. Titanium also eliminates galvanic coupling with the super-duplex rail body.

The 600 mm stroke bearing is integrated into a 150 mm × 150 mm titanium box beam with 8 mm wall thickness. Finite-element analysis shows the first Euler buckling mode at 9 800 N—four times the peak operational load. Titanium also eliminates galvanic coupling with the super-duplex rail body.

Condition monitoring without cables

MEMS accelerometers log vibration signatures every cycle; data is uplinked via acoustic modem to a topside digital twin that predicts spallation 200 hours in advance. Since deployment, unplanned interventions have dropped 85 %, saving an estimated $20 million per year across 40 wells.

MEMS accelerometers log vibration signatures every cycle; data is uplinked via acoustic modem to a topside digital twin that predicts spallation 200 hours in advance. Since deployment, unplanned interventions have dropped 85 %, saving an estimated $20 million per year across 40 wells.

Installation by robot

Rails are delivered in 3 m segments with titanium latch plates that snap together via bayonet locks actuated by an ROV manipulator. A laser alignment jig projects a green line onto the valve flange, achieving ±0.2 mm linearity in under 20 minutes. M24 titanium bolts are torqued to 800 Nm using an integral hydraulic wrench.

Rails are delivered in 3 m segments with titanium latch plates that snap together via bayonet locks actuated by an ROV manipulator. A laser alignment jig projects a green line onto the valve flange, achieving ±0.2 mm linearity in under 20 minutes. M24 titanium bolts are torqued to 800 Nm using an integral hydraulic wrench.

In the deep ocean, where a single service call costs $50 000, the linear motion bearing is no longer hidden—it is the silent hinge of offshore energy security.